Printer to serve multiple purposes, which is much preferred from bothĪ consumer and an environmental perspective. Traditional fabrication methods, this flexibility allows the individual Material compatibility make it possible for inkjet printing to offerīoth easy customization and short iteration times.

The on-demand droplet production and diverse Microarrays 13 including emulsion droplets 14 for polymerase chain reaction, 15 fabrication of microfluidics, 16− 18 metamaterials, 19 and flexible electronics 20-these are just a few examples of applications of Photonic crystals, 1− 4 tissue engineering, 5 (bio)chemical sensingĭevices, 6 drug loading 7− 11 and discovery, 12 droplet To an affordable system will inspire researchers to explore the possibilities Three or more reactants, where premature introduction can shift the The ability to do a quasi-simultaneous introduction of chemicals mayīe particularly useful for studies of rapidly reacting systems of

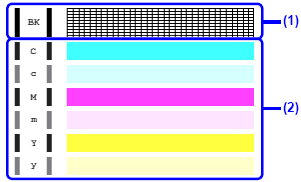

Quasi-simultaneous loading of reactants into microfluidic systems. With array-type printheads (in our case, 6 x 90 nozzles) allow for This loading method has promising applications within point-of-care Precision, we explore tunable loading of drug combinations into microdevices. Utilizing the expanded substrate compatibility and the increased print Second, spring loadingsĪre added to increase the print precision up to 50-fold, which facilitatesĪlignment to a pre-patterned substrate or between successive prints. (rigid, elastic, liquid, granular, and sticky). This enables printing on a diverse set of substrates Isolation bars are added to unlock multiple prints on the same substrate Inkjet printer to greatly increase its applicability. Modifications are introduced to a consumer-grade

0 kommentar(er)

0 kommentar(er)